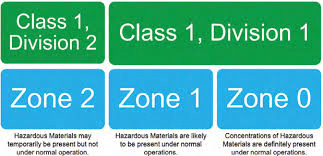

DIVISION MARKINGS

Article 500 Hazardous Locations, Classes I, II, and III, Divisions 1 and 2

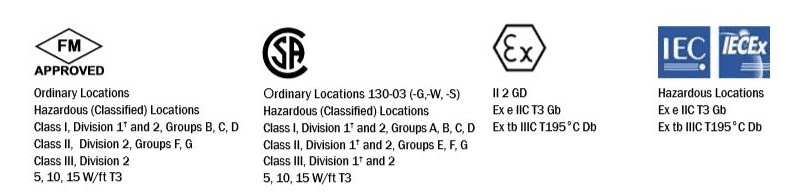

Articles 500 through 504 cover the requirements for electrical and electronic equipment and wiring for all voltages in Class I, Divisions 1 and 2; Class II, Divisions 1 and 2; and Class III, Divisions 1 and 2 locations where fire or explosion hazards may exist due to flammable gases, flammable liquid-produced vapors, combustible liquid-produced vapors, combustible dusts, or ignitible fibers/flyings.

Informational Note No. 1: The unique hazards associated with explosives, pyrotechnics, and blasting agents are not addressed in this article.

Informational Note No. 2: For the requirements for electrical and electronic equipment and wiring for all voltages in Zone 0, Zone 1, and Zone 2 hazardous (classified) locations where fire or explosion hazards may exist due to flammable gases or vapors or flammable liquids, refer to Article 505.

Informational Note No. 3: For the requirements for electrical and electronic equipment and wiring for all voltages in Zone 20, Zone 21, and Zone 22 hazardous (classified) locations where fire or explosion hazards may exist due to combustible dusts or ignitible fibers/flyings, refer to Article 506.

Informational Note No. 4: Text that is followed by a reference in brackets has been extracted from NFPA 497-2017, Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas, and NFPA 499-2017, Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installation in Chemical Process Areas. Only editorial changes were made to the extracted text to make it consistent with this Code.

Equipment that has been identified for a Division 1 location shall be permitted in a Division 2 location of the same class, group, and temperature class and shall comply with 500.8(B)(2)(a) or (B)(2)(b) as applicable.

- Intrinsically safe apparatus having a control drawing requiring the installation of associated apparatus for a Division 1 installation shall be permitted to be installed in a Division 2 location if the same associated apparatus is used for the Division 2 installation.

(b) Equipment that is required to be explosionproof shall incorporate seals in accordance with 501.15(A) or (D) when the wiring methods of 501.10(B) are employed.

Where specifically permitted in Articles 501 through 503, general-purpose equipment or equipment in general-purpose enclosures shall be permitted to be installed in Division 2 locations if the equipment does not constitute a source of ignition under normal operating conditions.

Equipment that depends on a single compression seal, diaphragm, or tube to prevent flammable or combustible fluids from entering the equipment shall be identified for a Class I, Division 2 location even if installed in an unclassified location. Equipment installed in a Class I, Division 1 location shall be identified for the Class I, Division 1 location.

Class I, Divisions 1 and 2

Seals installed in Class I, Division 1 and Division 2 locations shall comply with 501.15(C)(1) through (C)(6).

Exception: Seals that are not required to be explosionproof by 501.15(B)(2) or 504.70 shall not be required to comply with 501.15(C).

(1) Fittings

Enclosures that contain connections or equipment shall be provided with an integral sealing means, or sealing fittings listed for the location shall be used. Sealing fittings shall be listed for use with one or more specific compounds and shall be accessible.

(2) Compound

The compound shall provide a seal to minimize the passage of gas and/or vapors through the sealing fitting and shall not be affected by the surrounding atmosphere or liquids. The melting point of the compound shall not be less than 93°C (200°F).

(3) Thickness of Compounds

The thickness of the sealing compound installed in completed seals, other than listed cable sealing fittings, shall not be less than the metric designator (trade size) of the sealing fitting expressed in the units of measurement employed; however, in no case shall the thickness of the compound be less than 16 mm (5/8 in.).

(4) Splices and Taps

Splices and taps shall not be made in fittings intended only for sealing with compound; nor shall other fittings in which splices or taps are made be filled with compound.

(5) Assemblies

An entire assembly shall be identified for the location where the equipment that may produce arcs, sparks, or high temperatures is located in a compartment that is separate from the compartment containing splices or taps, and an integral seal is provided where conductors pass from one compartment to the other. In Division 1 locations, seals shall be provided in conduit connecting to the compartment containing splices or taps where required by 501.15(A)(1)(2).

(6) Conductor or Optical Fiber Fill

The cross-sectional area of the conductors or optical fiber tubes (metallic or nonmetallic) permitted in a seal shall not exceed 25 percent of the cross-sectional area of a rigid metal conduit of the same trade size unless the seal is specifically identified for a higher percentage of fill.