How Temperature Sensor Probes Are Useful for Industries

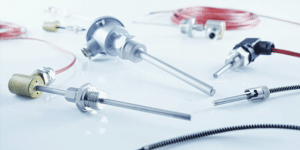

Temperature is one of the most common parameters used to measure, monitor, and control certain processes in various industries. Temperature Sensor probes are perhaps the best solution to collect accurate temperature measurements and improve application efficiency. We provide custom temperature sensor probes, and resistance temperature detection (RTD) solutions for industries. These are effectively used in many applications […]