Understanding Differences ATEX code

The ATEX code is an alphanumeric string that denotes the certification achieved by the product along with the environment and conditions it is suitable for.

The code can be broken down into a prefix, for example: CE0518 Ex II 2 G and suffix, for example: Ex d IIC T6 Gb.

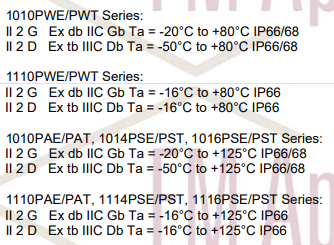

Products may carry more than one suffix for the same prefix which allows definition of applicability for different environments, for example Gas and Dust hazards.

- Part of the coding is the Equipment Category of which there are 5 variants, M1 & M2 for mine applications and 1, 2 or 3 for anything other than mining. As the number increases in size, the protection level falls such that the highest protection will always be 1 or M1. It is possible for some certifications to state more than one Equipment Category.

The final part of the suffix refers to the Environment which will be G for gases or vapours and D for combustible dusts.

Some devices may be dual certified for both Gas and Dust environments which means there will be a separate suffix for each to define the certification reached.

- The ATEX suffix gets into the detail of how the device is protected from causing an explosion when installed in a hazardous area and what that hazard conditions are.

The ATEX suffix always starts with Ex to indicate Explosion Protection and is then followed by 4 more sections whether it is for Gas or Dust applications. Many devices may show a separate suffix for Gas and one for Dust because they have achieved testing and certification for both hazards.

Types of protection?

There are many different methods of preventing ignition in a hazardous environment and Types of Protection define which has been used in a particular case. After the initial Ex, will follow either one or two letters to indicate the type of Protection. Some require a second character to stipulate the level of protection and therefore which hazardous area Zone or Category they apply to.

The most common Types of Protection employed with valves and measuring instruments are d (Ex d), e (Ex e), m (Ex m), n (Ex n) and ia (Ex ia).

Types d, e and m are all suitable for Zones 1 or 2, Category 2 or 3 unless they have a second character of a, b, or c which further limits this. Note that types of protection can be combined and de, em or me are all commonly seen.

Ex d is commonly and incorrectly known as explosion proof but it actually is described as flameproof. The housing will contain a flame without allowing it to escape to the hazardous atmosphere.

Ex e means increased safety referring to the lack of arcs, sparks or hot surfaces.

Ex m is encapsulation that prevents the atmosphere reaching any potentially incendive parts.

Ex n is similar to Ex m and means non-sparking which limits it to Zone 2, Category 3 environments.

Ex ia or intrinsically safe is suitable for Zone 0 or 20, Category 1. This achieved through limiting the energy of sparks and surface temperatures through very low power requirements.

Gas or dust?

The next section of the coding refers to the Gas Group or Dust Type of the hazardous environment for which compliance has been certified.

I is solely for mining applications.

II covers all gas hazards and is shown as IIA, IIB or IIC which relates to the potential gases that may be present.

III indicates dust hazards and again is split into IIIA, IIIB and IIIC categories. IIA relates to combustible flyings. IIIB is for non-conductive dusts and IIIC for conductive dusts.

In general, whether it is marked as II or III for the gas group, the C rating is always the safest as it relates to the biggest risk protection.